What arc fault protection means today

Arc fault protection has become one of the most critical pillars of modern electrical safety. An arc fault is a high-energy discharge caused when current jumps between damaged conductors, loose terminations, deteriorated insulation, or broken wiring. That discharge generates extreme temperatures capable of igniting surrounding materials.

Globally, a significant percentage of electrical fires in homes, offices, and industrial facilities originate from series and parallel arc faults that are not detected by traditional breakers or residual current devices.

For that reason, electrical safety standards have evolved. Magnetic and thermal circuit breakers are no longer enough. Differential protection is not enough. A dedicated Arc Fault Detection Device (AFDD) is required to actively detect an electrical signature that precedes a fire.

How arc fault protection works

Arc fault protection continuously analyzes electrical waveforms. An AFDD identifies distorted pulse signals that indicate a dangerous fault condition and immediately disconnects the circuit.

A modern AFDD includes:

-

Digital signal processing of current waveform

-

Algorithms to differentiate normal electrical noise from a true arc

-

A fast trip mechanism

By removing energy from the arc source, the AFDD eliminates the heat that triggers ignition and prevents catastrophic losses.

Where AFDD arc fault protection should be used

Arc-fault-protected circuits are recommended or required in:

-

Residential buildings and apartments

-

Bedrooms and rest areas

-

Hospitals and medical facilities

-

Schools and administrative buildings

-

Shopping centers and retail environments

-

Hotels and hospitality chains

-

Industrial plants

-

Vehicles, trains, marine and aviation systems

-

Long cable runs and multi-point socket circuits

The common denominator: any environment where degradation, vibration, humidity or noise may damage conductors.

Types of electrical arcs that must be detected

Effective arc fault protection addresses:

-

Series arc faults: caused by loose conductors or broken wires.

-

Parallel arc faults: between line-neutral or line-earth, with high ignition energy.

-

Arc-to-ground faults: where leakage generates a hazardous current path.

Conventional breakers are not designed to detect these patterns. Therefore, without arc-fault detection, the fire risk remains active.

Direct benefits of implementing arc fault protection

-

Prevents electrical fires at their origin

-

Reduces downtime and property damage

-

Protects occupants and personnel

-

Meets advanced safety regulations and standards

-

Intelligent operation minimizes nuisance tripping

-

Continuous monitoring of conductor condition

In simple terms, it delivers real preventive safety, not reactive mitigation.

CNC Electric AFDD: A high-performance arc-fault protection solution

Among available products, the AFDD device manufactured by CNC Electric stands out for incorporating:

-

MCU-based real-time arc signal analysis

-

Overload protection with long and short delay

-

Instant short-circuit protection

-

Protection against series arc faults

-

Protection against parallel arc faults

-

Arc-to-earth protection

-

Integrated 30 mA residual-current protection

-

Curve-C thermo-magnetic characteristics

-

Current ratings from 6 A to 63 A at 230 V

-

Multiple sensitivity modes selectable via front button

-

10,000 electrical and 20,000 mechanical cycles

This makes it suitable for residential, commercial, and industrial installations, including environments with heavy electromagnetic interference, where sensitivity adjustments reduce unwanted trips.

You can review full specifications on the manufacturer website:

https://www.cncele.com/es/afdd-fault-arc-protector-product/

How to select the right arc fault protection device

Before deploying AFDD protection, evaluate:

-

Circuit rated current (16 A, 20 A, 32 A, etc.)

-

Load type, including motors or power electronics

-

Cable length and degradation risk

-

Compliance requirements in your region

-

Required residual-current rating

-

Ambient temperature and environmental conditions

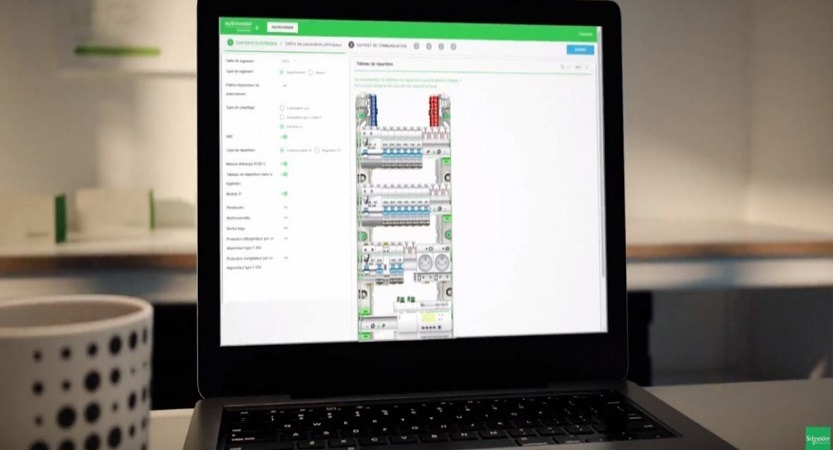

AFDD units are typically mounted on DIN-rail inside distribution boards, protecting final circuits without requiring a full wiring redesign.

Conclusion: Arc fault protection is no longer optional

Modern electrical safety has reached a new maturity level. Relying solely on miniature circuit breakers and RCDs is insufficient when the leading ignition source is an invisible arc fault inside the wiring system.

The solution is clear:

-

high-speed digital detection,

-

immediate disconnection,

-

real-time waveform analysis.

That is arc fault protection, and AFDDs bring installations into 21st-century fire-prevention standards.