Have you ever opened an electronic device and wondered how all those components stay together and work in harmony? The secret isn’t just in the chips and resistors, but in the PCB design behind them—one of the most important elements in any modern electronic device.

If you’re taking your first steps into the world of electronics and want to move from prototypes to professional final products, you’ve come to the right place. In this article, I will break down the most basic concepts of PCB design so you can understand not only what it is, but why it is so crucial.

What Exactly Is a PCB?

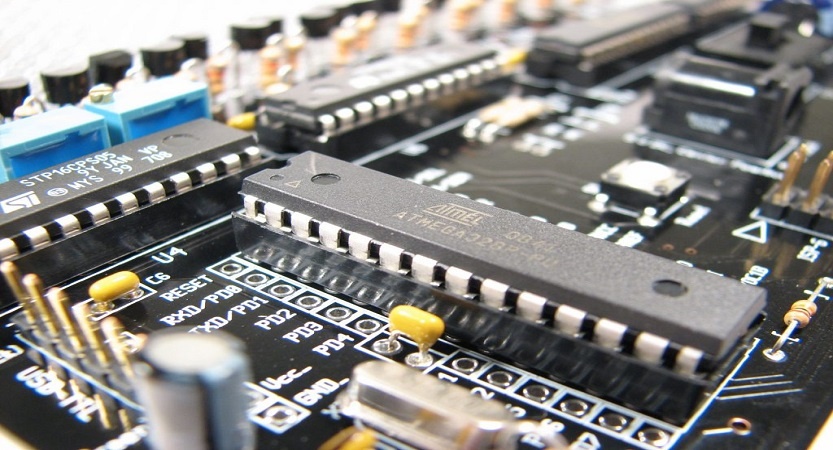

PCB stands for Printed Circuit Board. These are boards made of insulating material—typically fiberglass (FR-4)—that have thin copper traces adhered to their surface. These lines, known as traces, electrically connect electronic components, replacing the messy wiring of a typical prototype.

When I began my studies, my professor told me to think of a PCB as if it were a city map:

-

The components (microcontrollers, resistors, connectors) are the buildings.

-

The copper traces are the streets and highways connecting them.

-

The vias (small metalized holes) are the tunnels or overpasses linking different layers.

-

And the board itself is the terrain where everything is built.

The Essential Parts of a PCB: Know the Terrain

To understand PCB design, you must first become familiar with its fundamental elements:

- Substrate (Base): The insulating and rigid material that gives the board structure. FR-4 is the most common, but there are flexible PCBs and high-frequency materials for specific applications.

- Copper Layer: A thin laminated copper sheet over the substrate. During fabrication, the excess copper is removed, leaving only the traces and connection areas.

- Solder Mask: The lacquer layer covering the copper, usually green but available in many colors. It protects the copper from oxidation and prevents solder from spreading where it shouldn’t.

- Silkscreen: The visible text printed on top of the solder mask, usually white. It identifies components, values, and orientation (e.g., R1, C5, PIN 1).

The PCB Design Process: From Concept to Physical Board

Designing PCBs is not just drawing lines between components. It is a methodical process summarized in four key steps:

Schematic: The electrical diagram of your circuit. Here you define which components to use and how they connect. Accuracy is crucial—any mistake here will be replicated on the physical board.

Layout Design: This is where PCB design becomes tangible. You place the components from the schematic onto the board space. Proper placement improves efficiency. For example, keeping related components close reduces trace length. Mechanical constraints and heat dissipation must also be considered.

Routing: The process of drawing the copper traces that connect the components. Basic guidelines include:

-

Keep critical signal traces (like clocks) as short as possible.

-

Use trace widths appropriate for the current they will carry.

-

Avoid 90° angles.

We will analyze these in detail in future articles.

Fabrication Files (Gerber, BOM, etc.): When the design is finished, you don’t send your native design files. Instead, you generate standard fabrication files called Gerbers, BOM, and others. These act like blueprints for the manufacturer, indicating the details of each layer: copper, mask, silkscreen, drill holes, components, etc.

Why Is Good PCB Design So Important?

In PCB design, the goal is not just to make something that works. A good design is the difference between a reliable product and a problematic one.

-

Reliability: Prevents shorts and premature failures.

-

Performance: Poor design introduces electrical noise that affects signals.

-

Manufacturability: Errors may make the board difficult or expensive to produce.

-

Cost: An optimized design uses less space and material.

Conclusions

For me, PCB design is a fascinating discipline that combines creativity, logic, and precision. It is the foundation that transforms an abstract electronic idea into a functional, tangible product.

Mastering the basics, like what we’ve covered today, is the first essential step. In future articles, we will explore each stage more deeply: choosing trace widths, advanced routing strategies, impedance management, and more.

What topic would you like us to cover next? Do you have questions about any basic concept? Leave a comment and let’s talk electronics!