LOGO! Many may be familiar with this word and for others it may be the first time they read it. Today we will talk in depth about these devices created by SIEMENS. At the end of our article you will really be able to know everything you need to know about these devices and you will be able to answer the question whether it is really a PLC.

If you are interested in everything related to these topics, don’t forget to subscribe to our Newsletter so you won’t miss any article we publish. You can subscribe by clicking here.

Without further ado, let’s get started!

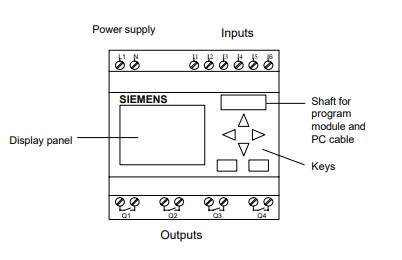

What is a LOGO!

LOGO! is considered by SIEMENS as a universal logic module. Some people also call it a specific purpose or compact PLC. If you do not know what a PLC is, we invite you to visit our article where we explain everything about it before you continue reading. You can see it here.

A LOGO! is a device capable of solving automation tasks framed in the field of installation and domestic. It was designed to support the replacement of the old logic of relays and contactors existing before the emergence of PLCs. It has internally a register of basic and special functions with which many low-difficulty automation solutions can be implemented. It can be used for special controls in greenhouses or winter gardens, small machine building applications, appliances and switch cabinets. Their compact size makes them perfect for simple wiring and mounting mainly on DIN rails in low-volume cabinets.

The following are some of the integrations supported by LOGO!

- Control

- Operating and display unit

- Power supply unit

- Interface for expansion modules

- Interface for program modules and PC cable

- Timing

- Binary marks

- Determined number of inputs and outputs depending on the model of the device layer.

There are a variety of models available that we will see during this article, but it is necessary to emphasize their wide range of possibilities and ranges of uses. There are models ranging from 12V to 240V in alternating and direct voltages, as well as numerous expansion modules that increase the versatility of these devices.

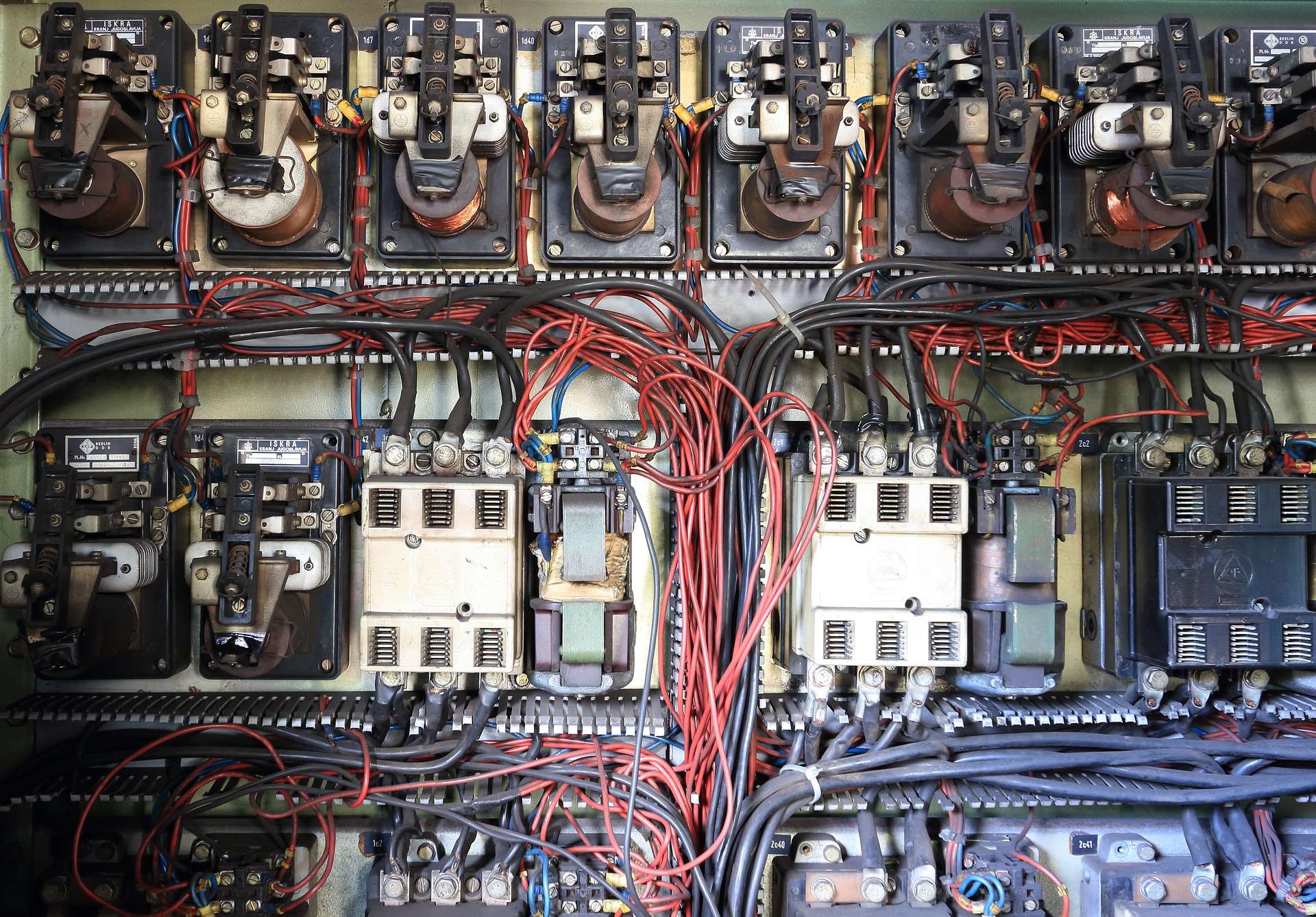

The rise of LOGO!

LOGO! came into being in 1996, so we have been using these devices for more than a quarter of a century. The main reason for their emergence was the migration from conventional hardwired functions to programmable functions programmed into LOGO! This led to a breakthrough in the development of traditional hardwired control to programmable control, providing a high degree of flexibility in troubleshooting. One of the main advantages of the migration to these devices was the clear savings in space and instrumentation to be mounted in the project cabinets, which in previous years were made with wired logic.

LOGO! versions

LOGO! V6 0BA5 series

In 2004 SIEMENS presents the 6th series of these devices, which have great advantages over their predecessors. By simply moving the wiring from the cabinet to alarm messages within the electrical enclosure of the LOGO! they have been able to concentrate twice as many functions in an even smaller space. All reports are easily displayed in text form, so operators can always know immediately what is happening.

External Display for LOGO V6

In 2008 SIEMENS got down to work and launched the external display for LOGO! with easy plug-and-play connection, taking the development of the LOGO! range to truly revolutionary levels. This made the handling and use of the machines increasingly easier.

LOGO V8

With the launch of this version in 2014 SIEMENS gives a blow to the table carrying out a great competitive advantage by allowing global access to these devices through web servers. LOGO! 8 offers its customers the possibility of being able to remotely monitor all equipment connected to the production process controlled by this LOGO! This allows production planning and the creation of maintenance actions by technicians.

We will now introduce this device and look at its technical characteristics.

LOGO! V8 features

As we have seen above, the LOGO! V8 is the latest model of these devices, although it has had subsequent updated versions.

There are two main types of these devices, which are subdivided into 2 categories:

- SIEMENS LOGO! V8 Basic module with display.

- SIEMENS LOGO! V8 Basic module without display.

1. SIEMENS LOGO! V8 Basic module with display

- It has an interface for the connection of expansion modules.

- Supports up to 24 DI, 20 DO, 8 AI and 8 AO expansion modules (DI-Digital Inputs, DO-Digital Outputs, AI-Analog Inputs and AO-Analog Outputs).

- It has an integrated web server.

- Ethernet physical communication interface.

- Standard micro CF card slot.

2. SIEMENS LOGO! V8 Basic module without display

- Relay outputs with maximum output current of 10A.

- Micro CF card slot (optional).

- Built-in EEPROM memory for control program storage.

- Real time RTC with automatic time change.

- It has 8 DI and 4 DO

- It has 4 AI of 12/24VDC or 0 to 10V variants. These inputs can be used as DI if required.

- Supports up to 24 DI, 20 DO, 8 AI and 8 AO in expansion modules (DI-Digital Inputs, DO-Digital Outputs, AI-Analog Inputs and AO-Analog Outputs).

- Connection to TDE text display for LOGO! 8 via Ethernet port.

SIEMENS LOGO! V8 models

In the previous section we saw the basic models of the LOGO! 8. It should be noted that there are 4 versions for each of these two LOGO! V8 models. In this case, the 4 versions of the Basic Module with display have the same technical characteristics as the 4 versions of the Basic Module without display. In order not to become repetitive, we will make a table with 2 versions of each model and in this way we will cover everything.

Technical Characteristics of SIEMENS LOGO! V8

LOGO! 24CE / LOGO! 24CEO |

LOGO! 12/24RCE / LOGO 12/24RCEO |

LOGO! 24RCE / LOGO! 24RCEO |

LOGO! 230RCE / LOGO! 230RCEO |

|

Voltage Power supply |

24 VDC | 12…24 VDC | 24 V AC/DC | 115…230 V AC/DC |

Short-circuit protection |

Electronics(1A) | External fuse required | External fuse required | External fuse required |

Monitor |

YES/NO | YES/NO | YES/NO | YES/NO |

Analog inputs(AI) |

4 | 4 | – | – |

Outputs |

4; Transistors | 4; relay | 4; relay | 4; relay |

Working Temperature |

0-55 0C | 0-55 0C | 0-55 0C | 0-55 0C |

Web Server |

YES | YES | YES | YES |

Programming Cable |

Ethernet | Ethernet | Ethernet | Ethernet |

Protection Index |

IP20 | IP20 | IP20 | IP20 |

Installation |

DIN rail 35mm, 4 space units | DIN rail 35mm, 4 space units | DIN rail 35mm, 4 space units | DIN rail 35mm, 4 space units |

As we have seen in the table above, the 4 versions of each model have the same technical characteristics, since their main difference is the ability to have an integrated display.

SIEMENS accessories for LOGO! V8

-

LOGO! 8 HMI Text Display (6ED1055-4MH08-0BA1)

This text display with HMI function has 6 lines and 3 background colors. It includes 2 Ethernet ports for connection, as well as the installation accessories for this device. In this screen you can configure and attend the alarms and alerts of the LOGO! 8.

-

Front Panel Mounting Kit

These kits are used to mount LOGO! in places where temperature conditions are a bit more extreme than they were designed to work. They are added as extra protection to protect these devices from the environment in which they are operating.

-

Software LOGO! Soft Comfort V8

This is the software developed by SIEMENS for the programming of these devices. It supports most of the currently existing Operating Systems. It includes all the necessary licenses and documentation to be able to program the LOGO! 8.

Up to this point we have seen all the LOGO! 8 models offered by SIEMENS, as well as their versions and accessories that may be useful for some specific projects. Next we will see the expansion modules that these devices have in case their default inputs and outputs are insufficient.

Expansion modules for SIEMENS LOGO! V8

| Model | Number of Inputs (DI/AI) | Number of Outputs (OD/AO) | Voltage Power Supply |

LOGO! DM8 24 (6ED1055-1CB00-0BA2) |

4 DI 24 VDC | 4 DO 24 VDC, 0.3A | 24 VDC |

LOGO! DM16 24 (6ED1055-1CB10-0BA2) |

8 DI 24 VDC | 8 DO 24 VDC, 0.3A | 24 VDC |

LOGO! DM8 12/24R (6ED1055-1MB00-0BA2) |

4 DI 12…24 VDC | 4 relay outputs 5A | 12…24 VDC |

LOGO! DM8 24R (6ED1055-1HB00-0BA2) |

4 DI 24 V AC/DC | 4 relay outputs 5A | 24 V AC/DC |

LOGO! DM16 24R (6ED1055-1NB10-0BA2) |

8 DI 24 VDC | 8 relay outputs 5A | 24 VDC |

LOGO! DM8 230R (6ED1055-1FB00-0BA2) |

4 DI 115…230 V AC/DC | 4 relay outputs 5A | 115…230 V AC/DC |

LOGO! DM16 230R (6ED1055-1FB10-0BA2) |

8 DI 115…230 V AC/DC | 8 relay outputs 5A | 115…230 V AC/DC |

LOGO! AM2 (6ED1055-1MA00-0BA2) |

2 AI (0-10V o 0-20mA) | – | 12…24 VDC |

LOGO! AM2 PT 100 (6ED1055-1MD00-0BA2) |

2 AI for Pt100(Temperature range -50 to 200) | – | 12…24 VDC |

LOGO! AM2 AQ (6ED1055-1MD00-0BA2) |

– | 2 AO (0 to 10V, 0 to 20mA, 4 a 20mA) | 24 VDC |

LOGO! vs PLC

During the previous sections we have seen the features of the LOGO!, its functionalities, accessories and all the expansion modules with which it can be integrated. If you have come this far, you have surely noticed the broad similarities that a LOGO! has with a PLC, but…. Is a LOGO! really a PLC?

We’ll give our opinion below and we’d love to open a debate on the subject in the comments, so don’t forget to leave your opinion.

Our opinion

Speaking from our experience and individual opinion if we consider that a LOGO! does fall into the category of PLC.

In our article we made clear everything you need to know about PLCs, and based on the same concept that we use to define these devices, we can see perfectly that the category of LOGO! falls within the concept of Programmable Logic Device.

But be careful, we do not consider that a LOGO! can be compared with a high performance PLC, such as the MODICON range of Schneider Electric or the SIMATIC of SIEMENS. We consider that it can be called a low performance PLC or PLC for low complexity applications, which were really the purpose of its creation. With this device we can solve automation problems that with industrial PLC would be somewhat excessive.

It should be noted that these devices have a number of features and power significantly lower than their larger industrial brothers, which limits its capabilities to less complex problem solving and operating environments somewhat less aggressive.

In our next article we will be talking about the direct competition of this device, the ZELIO, which comes from Schneider Electric. If you would like to read a bit about the rivalry of solutions from these two great manufacturers, you can visit our article on this topic by clicking here.

To Finish

We hope that this article about SIEMENS LOGO! has provided you with a new range of solutions and knowledge. If so, don’t forget to leave us a nice Like and share on your social networks so that all your friends and followers can also benefit from our content.

Let us know in the comments what you thought of this range of devices and if you agree with our opinion about it.

Remember that we have a Telegram Channel where we are constantly sharing valuable content that is sure to be of great benefit to you. Join here!

Without further ado, I’ll say goodbye until the next article.

Really great article, thank you

Thanks