As part of this new proposal for you called Automated Systems, we bring you the second article where we will talk about Actuators. In the first article we explained the types, categories of sensors and their operation, if you have not seen it yet, we invite you to take a look by doing click here.

Without further ado, we begin!

What are actuators?

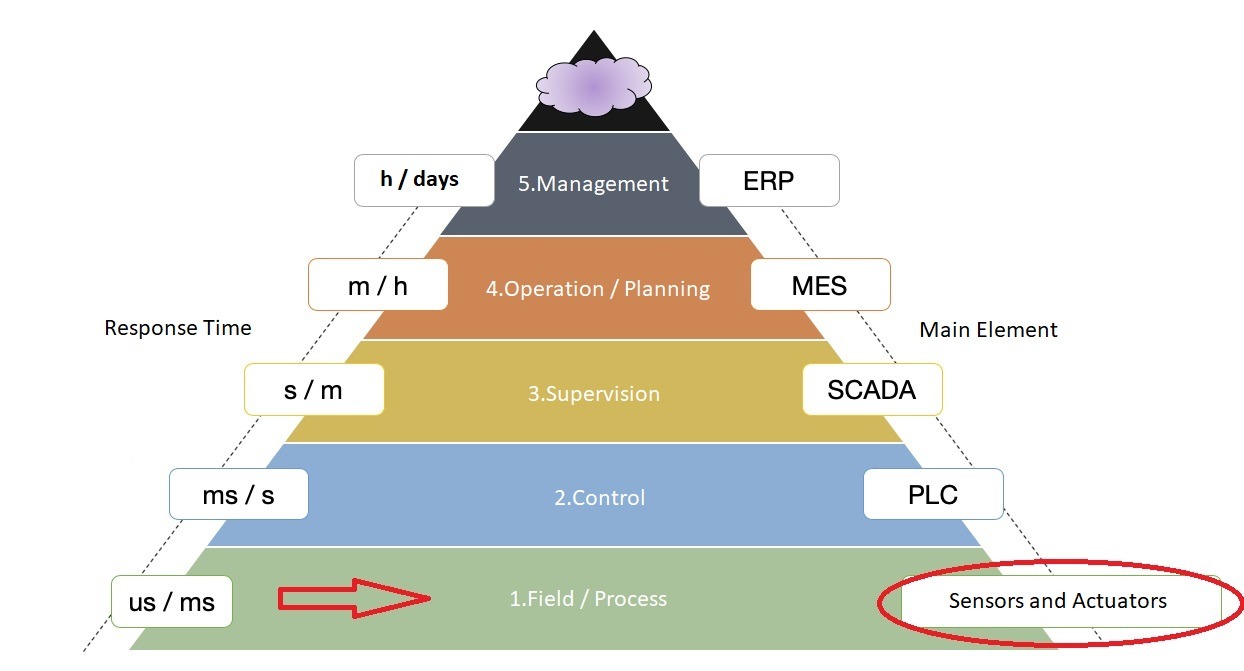

In the previous article we were also studying the Automation Pyramid, where the hierarchy of the elements that make up an automation system was shown. In these two articles we will focus on the first level, where the field devices are located: Sensors and Actuators.

Actuator

According to Especificar Magazine an actuator is a device that converts energy into motion or is used to apply force. The device takes energy from a certain source (which can be energy created by air, liquid or electricity) and converts it into the desired movement. The two types of basic movement desired are linear and rotary, but oscillatory movement is also common.

Actuators that work by converting energy into straight linear movements serve to push or pull. Rotators, on the other hand, convert energy into oscillatory movements and are generally used in different valves, such as butterfly or ball valves.

Actuator types

- Mechanical: Mechanical actuators work by converting from one type of motion (eg rotary motion) to another type of motion (eg linear motion). These actuators employ a combination of components to operate, including gears, pulleys, chains, springs, and rails, among others.

- Pneumatic: Pneumatic actuators are mechanisms that convert the energy in compressed air into mechanical work. Pneumatic cylinders, regardless of their construction form, represent the most widely used pneumatic actuators.

- Hydraulic: These actuators are based, for their operation, on the pressure exerted by a liquid, generally a type of oil. The machines that are normally made up of hydraulic actuators have higher speed and greater mechanical resistance and are large, therefore, they are used for applications that require a heavy load.

- Electrical: Electric actuators are devices that incorporate an electric motor and a reducer that allows any device to be operated to carry out a certain movement or action. For example, they are used in the industry to operate gates, valves and, in general, different elements that put one process in communication with another or a state of a process with another. The electric actuator is the one that stores the valve and stroke data, and subsequently, this information is processed by the control part that is responsible for connecting and disconnecting it according to the needs.

Actuator Applications

Among the main applications of these devices that we can find are the following:

If we mention the mechanical actuators, we can not fail to highlight its high reliability, simplicity of use, its minimal need for maintenance, safety and positioning accuracy. In manual applications are integrated as add-ons for switches and security systems. Thanks to its features and simplicity to find a quick and effective solution for almost any application.

Hydraulic actuators are normally used when we need strength in our system, so generally used when we need a heavy burden. Must take into account that require a lot of equipment for power supply and high frequency maintenance.

In the case of pneumatic actuators are the most common type of actuator and used, because its energy source is compressed air. One of the most common applications is in operation of butterfly valves. This type specific, can be found in many systems as they are actuators that respond quickly to start and stop operations, are of the cheapest we can find in the market and more reliable than other categories.

Electric actuators for its part, between its applications is its use in medium-sized robots, since they require a high speed or other power operated hydraulic or pneumatic actuators. Brushless servomotors Alternating Current (AC) are also used as positioning actuators, thanks to its low rate of maintenance.

Conclusions

In a very simple and direct way we have seen what actuators consist of, their types, as well as their operation and applications. We can independently understand what function these devices perform in an Automated System.

With this article we will finish the base of the instrumentation of the Automation Pyramid and we will proceed to escalate towards the Control Systems, where we will be seeing the function that these systems have independently and we will make the relation of how to use them with a small example that includes the themes we’ve seen so far.

We hope you liked the article. If so, let us know with a Like. If you have any questions or concerns, please leave them in the comments and we will respond to them.

Remember to join our community at Facebook, follow us onTwitter and review our most exclusive content at Intagram.