Today we want to bring you a topic that we cannot stop talking about in automation: The HMI!

Before continuing reading we recommend that if you have not yet visited our article “PLC, everything you need to know”, please do it before continuing with this one as it will provide you with the basic knowledge about Programmable Automatons.

Without further ado, let’s get started!

What are HMI?

The Human Machine Interface or Human Machine Interface (HMI) is nothing more than a set of devices that allow interaction between technical personnel and the process. It is the main tool used for the coordination and control of industrial processes.

One of its main functions is to display in real time the information on the variables involved in the automated process. Such as temperature, pressure, conductivity, power, valve opening and closing, pump status, among many others.

They are capable of making graphs of historical values for subsequent analysis and in real time in order to optimize the automated system to the maximum.

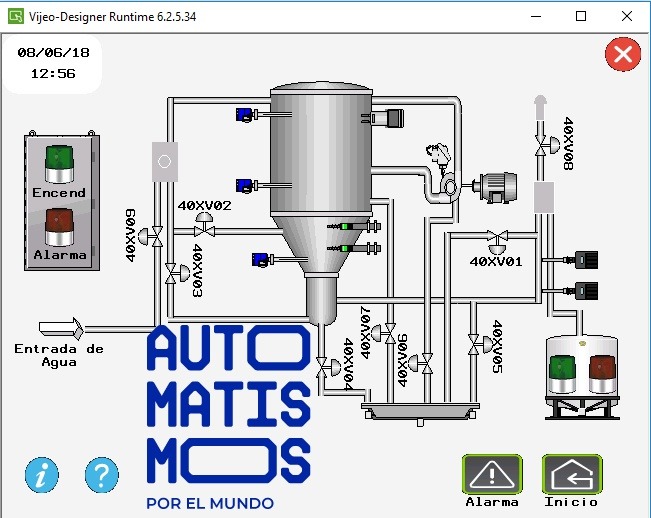

The image above shows an HMI designed for the automation and control of a thermocompression water still. It consists of a group of pressure, level and temperature probes, electro-pneumatic valves, a blower and several pilot lights to indicate the operating states of the system.

Some HMI models

Currently in the market for Human Machine Interfaces there are numerous variants to make a selection of an optimal device for our needs.

There are manufacturers like SIEMENS with its Comfort Panles, Schneider Electric with its Magelis, Omron with the NS / NB series and Allen Bradley with the Panel View, to mention the most used. You should always bear in mind that the criteria for use vary greatly and depend a lot on the representation of each of the companies in the different geographical areas.

|

|

|

|

|

Common doubt: HMI = SCADA?

This is one of the most common doubts that many users have when they hear each of these two concepts. Below we will make it clear if we are really talking about the same thing or not.

SCADA

Supervisory Control And Data Acquisition is its meaning.

SCADAs are used to monitor and control large spaces, usually an entire production plant. SCADA systems are a combination of subsystems that include, from field devices (sensors and actuators), to RTUs (Remote Control Terminals), PLC and HMI.

The data from each of these subsystems is sent to SCADA, which has its own HMI, and that is where the greatest confusion on this issue lies.

We make it clear this way: An HMI can be part of a SCADA, but a SCADA cannot be part of an HMI.

Let’s see it illustrated in the following image:

As you can see, the field devices pay their signals to each subsystem governed by an RTU, which in turn has its own HMI to view and control the subsystem data locally. Then each of these two subsystems tributes the information to the main PLC or RTU. Each one processes it and finally sends it to the SCADA to view and control it completely from the computer in this case.

Below, you will see the video example of everything that the SCADA solution encompasses today, its interrelation with the Industry 4.0 and all the advantages of its use.

To end

With this short, but concise article, we wanted to point out the basics of Human Machine Interfaces and what they are used for. We hope that the doubt about the difference between an HMI and a SCADA system has evaporated, since it is something very recurrent in this topic.

We hope you liked the article. If so, leave us a Like and share it so that more readers can benefit.

Remember to subscribe to our Newsletter and support us in our social networks. If you have any particular questions, you can contact us through our email or raise them in our community Facebook.

by modbus RTU, can we replicate the HMI screen of the field device into the central SCADA system? meany can we see the same grapihics and data of HMI into the SCADA? if not how it’s possible?

Thanking you and looking forward for your reply.